Report: The Rising Demand for Reefer Trucking in Pharmaceuticals

In recent years, the pharmaceutical industry has grown rapidly, leading to an increased demand for reliable and efficient transportation solutions. In fact, the global pharmaceutical logistics market is expected to reach $98.32 billion by 2026.

One such solution taking the spotlight is reefer trucking, which offers temperature-controlled transport for sensitive pharmaceutical products.

In this article, we explore the growing demand for reefer trucking in the pharmaceutical industry and the new opportunities it presents for moving these crucial goods.

The Rise of Pharmaceutical Transportation

As the pharmaceutical industry continues to expand rapidly, the demand for reliable and efficient transportation solutions has never been higher. Pharmaceuticals account for 70% of the total temperature-controlled products market.

With the rise in global pharmaceutical sales and the increasing need for temperature-controlled transportation, reefer trucking has emerged as a critical solution to meet the growing demand for pharmaceutical transport.

Reefer or refrigerated trucking involves specialized trucks equipped with advanced temperature-controlled systems, ensuring that pharmaceutical products are transported in ideal conditions.

This type of transportation is essential for maintaining the efficacy and safety of temperature-sensitive medications and vaccines, which often require strict temperature ranges during transit.

The Science Behind Reefer Trucking & Pharma Product Preservation

Reefer trucking relies on advanced technology and scientific principles to preserve pharmaceutical products during transportation. The main objective is to maintain specific temperature ranges crucial for the stability and efficacy of these sensitive medications and vaccines.

1) Temperature Control Systems

Reefer trucks are equipped with sophisticated temperature control systems that allow for precise regulation of the internal environment. These systems use a combination of sensors, thermostats, and cooling mechanisms to maintain the desired temperature range throughout the journey.

The temperature control systems in reefer trucks are designed to be highly accurate and reliable. They can maintain temperatures within a narrow range, often with variations of only a few degrees. This level of precision is essential to safeguard the integrity and effectiveness of pharmaceutical products.

2) Monitoring and Data Logging

Reefer trucks often have monitoring and data logging capabilities to ensure the temperature control systems function optimally. These features allow real-time monitoring of temperature conditions inside the truck and record the data for analysis and validation purposes.

Temperature sensors placed strategically within the truck constantly measure the internal temperature and relay the information to a central monitoring system. Alerts are triggered if there are any deviations from the desired temperature range, enabling prompt corrective actions.

Data logging enables the collection of temperature data throughout the transportation process. This data can be analyzed retrospectively to identify any temperature excursions or deviations that may have occurred during transit. Such insights are crucial for quality control and regulatory compliance.

3) Insulation and Airflow Management

In addition to temperature control systems and monitoring, reefer trucks are designed with specialized insulation and airflow management features. These elements are vital in maintaining a stable internal environment and preventing temperature fluctuations.

Insulation materials with high thermal resistance minimize heat transfer between the external environment and the cargo area. This insulation helps to create a barrier that reduces temperature fluctuations caused by external factors such as ambient temperature changes or direct sunlight exposure.

Airflow management systems ensure the proper circulation and distribution of cooled air within the cargo area. This prevents temperature stratification and provides uniform cooling throughout, minimizing the risk of localized hotspots or cold spots.

4) Training and Compliance

The successful transportation of pharmaceutical products using reefer trucks requires trained personnel who understand the importance of temperature control and product preservation. Drivers and logistics personnel undergo specialized training to handle these sensitive goods and comply with regulatory guidelines.

Training programs cover proper loading and unloading procedures, temperature control system operation, emergency response protocols, and adherence to Good Distribution Practices (GDP) specific to the pharmaceutical industry.

Compliance with regulatory standards is essential in the pharmaceutical industry to ensure product safety and integrity. Reefer trucking companies must adhere to guidelines set forth by regulatory bodies such as the World Health Organization (WHO), the Food and Drug Administration (FDA), and other relevant authorities.

Key Takeaway

As the pharmaceutical industry continues to grow and evolve, the demand for reefer trucking is expected to increase further. Meeting the transportation needs of temperature-sensitive pharmaceuticals will remain critical to ensuring patient safety and delivering these crucial medical supplies effectively.

Latest Trends and Innovations in Reefer Trucking for Pharma Products

Reefer trucking for pharmaceutical products continues to evolve as technological advancements and industry practices drive innovation. Here are some of the latest trends and innovations shaping the field:

1) IoT Integration

The Internet of Things (IoT) has made significant strides in the logistics industry, and reefer trucking is no exception. IoT integration enables real-time monitoring of various parameters beyond just temperature, such as humidity levels, light exposure, and even shock or vibration.

This enhanced visibility allows for proactive measures to maintain optimal conditions and quickly address any issues that may arise during transportation.

2) Telematics and GPS Tracking

Reefer trucks are increasingly equipped with telematics systems and GPS tracking devices. These technologies provide real-time information about the location, route, and status of the truck and its cargo.

This level of transparency and traceability enhances security, reduces the risk of theft or tampering, and enables better coordination between logistics teams and pharmaceutical companies.

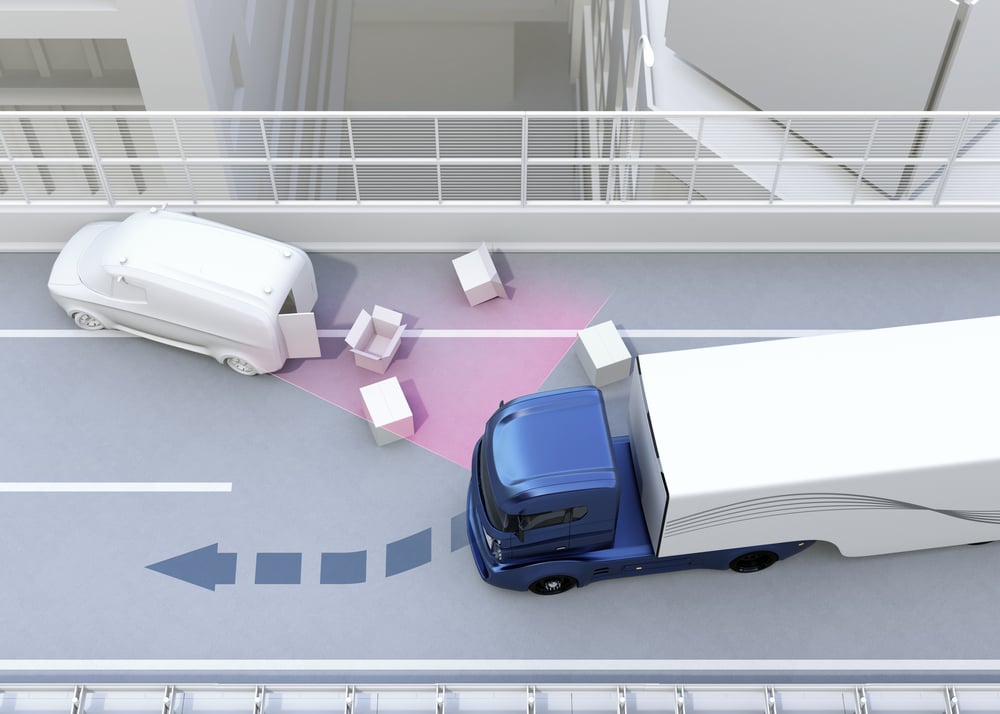

3) Autonomous Reefer Trucks

The emergence of autonomous vehicle technology is transforming the transportation industry, and reefer trucking is exploring its potential applications. Autonomous reefer trucks have the potential to improve efficiency, reduce human error, and optimize delivery routes.

While full autonomy is still in the testing and development phase, integrating autonomous features, such as lane-keeping and adaptive cruise control, is gaining traction.

4) Green Initiatives

Sustainability and environmental consciousness are becoming increasingly important in the transportation sector. Reefer trucking companies are adopting eco-friendly practices to reduce their carbon footprint.

This includes using energy-efficient refrigeration systems, exploring alternative fuel sources such as electric or hydrogen-powered vehicles, and implementing route optimization strategies to minimize mileage and fuel consumption.

5) Blockchain Technology

Implementing blockchain technology in reefer trucking can enhance transparency, security, and trust within the pharmaceutical supply chain.

Blockchain enables the creation of an immutable and decentralized record of all transactions and temperature data, ensuring the integrity and traceability of pharmaceutical products throughout their journey.

This technology has the potential to streamline compliance with regulatory requirements and simplify audits.

6) Cold Chain Packaging Innovations

Reefer trucking is closely intertwined with cold chain packaging solutions. Innovative packaging materials and designs are being developed to improve insulation, reduce thermal energy transfer, and enhance product protection.

Advanced packaging solutions, such as vacuum-insulated panels, phase change materials, and temperature-monitoring smart labels, are gaining traction to ensure the integrity of pharmaceutical products during transit.

7) Data Analytics and Predictive Maintenance

Collecting and analyzing data generated by reefer trucks enable proactive maintenance and predictive analytics. By analyzing historical temperature data, maintenance schedules can be optimized, and potential issues can be detected early.

Predictive maintenance helps prevent breakdowns and ensures the reliability of temperature control systems, reducing the risk of product spoilage or quality deviations.

Key Takeaway

The field of reefer trucking for pharmaceutical products is witnessing continuous advancements and innovative solutions. IoT integration, telematics, autonomous features, sustainability initiatives, blockchain technology, cold chain packaging innovations, and data analytics drive the industry forward.

As these trends and innovations are refined and adopted, the pharmaceutical industry can expect enhanced efficiency, safety, and quality in transporting temperature-sensitive products.

Regulations and Compliance in Reefer Trucking for Pharmaceutical Transportation

The transportation of pharmaceutical products via reefer trucks is subject to stringent regulations and compliance requirements to ensure these sensitive goods' safety, efficacy, and integrity. Here are some key aspects of regulations and compliance in reefer trucking for pharmaceutical transportation:

1) Good Distribution Practices (GDP)

GDP guidelines provide a framework for maintaining the quality and integrity of pharmaceutical products throughout the supply chain, including transportation. Reefer trucking companies involved in pharmaceutical transportation must adhere to GDP guidelines specific to their respective regions.

These guidelines cover various aspects, including temperature control, documentation, personnel training, and quality management systems.

2) Temperature Monitoring and Documentation

Temperature monitoring is critical to compliance in reefer trucking for pharmaceutical transportation. Reefer trucks must have accurate and calibrated temperature monitoring systems to record and document temperature conditions during transit.

Temperature data and other relevant information, such as product identification, shipping details, and driver information, must be appropriately documented and maintained for regulatory purposes.

3) Regulatory Bodies and Guidelines

Regulatory bodies, such as the World Health Organization (WHO), the Food and Drug Administration (FDA), and local health authorities, establish guidelines and regulations specific to pharmaceutical transportation.

These guidelines outline the acceptable temperature ranges, handling procedures, and documentation requirements for different types of pharmaceutical products. Reefer trucking companies must stay updated with these guidelines and ensure compliance with the relevant regulatory bodies.

4) Validation and Qualification

Reefer trucks used for pharmaceutical transportation often undergo validation and qualification processes to ensure their suitability.

This involves verifying and documenting that the temperature control systems, monitoring devices, insulation, and other critical components meet the necessary standards. Validation and qualification procedures ensure that the reefer trucks can maintain the required temperature conditions throughout transportation.

5) Security and Chain of Custody

Security measures are crucial to prevent theft, tampering, or unauthorized access to pharmaceutical shipments during transportation.

Reefer trucking companies must implement protocols to ensure the integrity and security of the cargo, including vehicle tracking systems, secure loading and unloading procedures, and seal verification processes. Maintaining a secure chain of custody is essential for regulatory compliance and maintaining product safety.

6) Audits and Inspections

Regulatory bodies and pharmaceutical companies may conduct audits and inspections to assess compliance with regulations and guidelines. These audits typically include reviewing documentation, temperature records, training records, and the overall adherence to GDP requirements.

Reefer trucking companies must be prepared for audits and maintain accurate and up-to-date records to demonstrate compliance.

7) International Standards

In addition to regional regulations, international standards such as the International Air Transport Association's (IATA) Perishable Cargo Regulations (PCR) and the Pharmaceutical Cargo Security Coalition (PCSC) guidelines provide further guidance for reefer trucking companies involved in global pharmaceutical transportation.

Adhering to these international standards ensures consistency and compliance across borders.

Key Takeaway

Compliance with regulations and adherence to best practices in reefer trucking for pharmaceutical transportation is of utmost importance to protect pharmaceutical products' quality, safety, and efficacy.

Reefer trucking companies must invest in robust processes, training, and technology to ensure compliance with regulatory requirements and maintain the trust of the pharmaceutical industry.

Choosing the Right Reefer Partner for Your Pharma Business

Selecting the right reefer trucking partner is crucial for the success of your pharmaceutical business. Here are some key factors to consider when choosing a reefer trucking provider:

1) Expertise and Experience

Look for a reefer trucking partner with expertise and experience in pharmaceutical transportation. They should deeply understand the industry's unique requirements, regulations, and best practices.

Experience in handling temperature-sensitive products and knowledge of cold chain logistics is essential to ensure safe and reliable transportation for your pharmaceutical goods.

2) Temperature Control Capabilities

Verify that the reefer trucking provider has well-maintained and technologically advanced equipment with reliable temperature control systems. Inquire about the range of temperature options available and the precision of temperature control.

The provider should demonstrate a commitment to maintaining the required specifications throughout transportation.

3) Compliance and Certifications

Ensure that the reefer trucking partner complies with relevant regulations and holds necessary certifications. Check if they have implemented Good Distribution Practices (GDP) and adhere to guidelines set by regulatory bodies such as the WHO and FDA.

Certifications like the International Organization for Standardization (ISO) 9001:2015 further validate their commitment to quality and compliance.

4) Security Measures

Pharmaceutical products require secure transportation to prevent theft, tampering, or unauthorized access. Inquire about the reefer trucking provider's security protocols, including vehicle tracking systems, seal verification procedures, and driver background checks.

Robust security measures should be in place to maintain the integrity and chain of custody of your pharmaceutical shipments.

5) Records and References Tracking

Research the reefer trucking provider's track record and reputation in the industry. Ask for references or case studies showcasing their successful transportation of pharmaceutical goods. A reliable partner will have a proven track record of delivering pharmaceutical products safely and on time.

Cargobot: Your Trusted Reefer Trucking Partner for PTL Freight

![]()

When choosing a reefer trucking partner for your pharmaceutical business, Cargobot stands out as a trusted and reliable option for moving PTL (Partial Truckload) freight. Cargobot is a technology-driven freight marketplace that connects shippers with carriers, providing efficient and cost-effective transportation solutions.

Cargobot offers a network of reputable carriers with expertise in pharmaceutical transportation, including reliable reefer trucking services. With their advanced technology platform, you can easily access competitive rates, real-time tracking, and transparent communication throughout the transportation process.

Their commitment to compliance, security, and customer satisfaction makes them an ideal choice for pharmaceutical businesses. Cargobot ensures that carriers in their network meet the necessary regulatory requirements, maintain temperature control systems, and have a proven track record in transporting temperature-sensitive products.

Partnering with Cargobot ensures that your pharmaceutical products are transported safely, efficiently, and in compliance with regulations. Take advantage of their advanced platform and network of trusted carriers to streamline your logistics operations.

Contact Cargobot today to discuss your pharmaceutical transportation needs and experience the benefits of their reliable reefer trucking services for moving PTL freight. Your pharmaceutical products are safe with Cargobot as your trusted logistics partner.

Learn more about finding the right PTL transport partner for your company with our free guide.